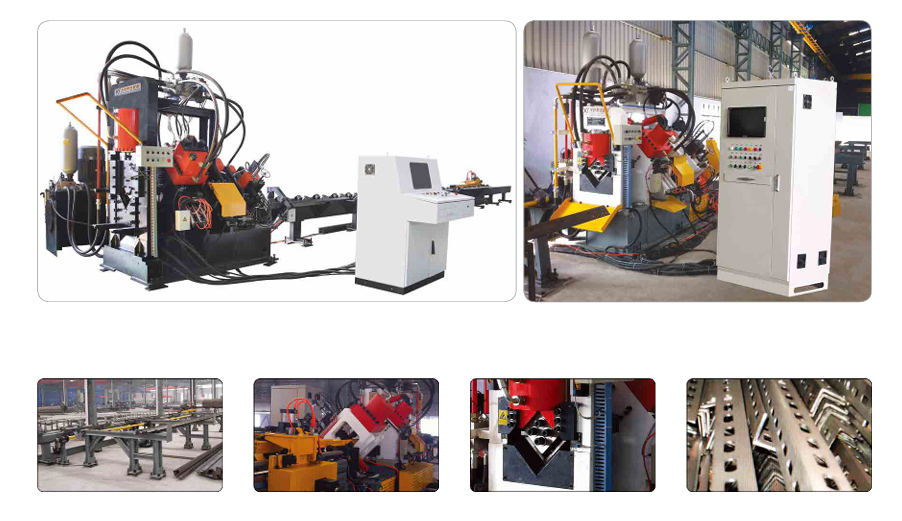

| MODEL | 2020 | 1612 |

|---|---|---|

| Angle steel size (mm) | L56 × 56 × 4—L200 × 200 × 20 | L40 × 40 × 4—L160 × 160 × 12 |

| Max. punch hole (dia. × thi.) (mm) | Φ26 × 20 (16mm, Q345) | Φ26 × 12 (10mm, Q345) |

| Punching force (kN) | 1000 | 600 (double station) or 1000 (single station) |

| Typing force (kN) | 1000 | 1000 |

| Shearing force (kN) | 1500 | 700 or 1000 (optional) |

| Max. length of blank (m) | 12 | 12 |

| Max. length of finished (m) | 10 | 10 |

| Qty. of punch on each side | 3 | 2 or 3 (optional) |

| Qty. of typing group | 4 | |

| Character size (mm) | 14 × 10 × 19 | |

| CNC axis | 3 | |

| Shearing mode | Double blade shearing | Single blade shearing |

| Feeding speed (m/min) | 90 | |

| Punching speed (min⁻¹) | 50–60 times/min | |

| Processing precision | Accordable with GB/T2694 | |

| Program function | Real time fault display | |

| Programming mode | Input by keyboard, USB interface | |

| Specification | Value |

|---|---|

| Angle steel size (mm) | L40 × 40 × 3—L100 × 100 × 10 |

| Max. punch hole (dia. × thi.) (mm) | Φ26 × 10 (8mm, Q345) |

| Punching force (kN) | 600 / 750 |

| Typing force (kN) | 700 |

| Shearing force (kN) | 1200 |

| Max. length of blank (m) | 12 |

| Max. length of finished (m) | 12 |

| Qty. of punch on each side | 2 / 3 |

| Qty. of typing group | 4 |

| Character size (mm) | 14 × 10 × 19 |

| CNC axis | 3 |

| Shearing mode | Single blade shearing |

| Feeding speed (m/min) | 90 |

| Punching speed (min⁻¹) | 50–60 times/min |

| Processing precision | Accorded with GB/72694 |

| Real time fault display | Yes |

| Programming mode | Input by keyboard, USB interface |

| Item Name | Numerical Value |

|---|---|

| Angle steel size (mm) | L63 × 63 × 4—L140 × 140 × 10 |

| Channel steel size (mm) | 8#–18# |

| Band steel size (mm) | 70 × 5–180 × 10 |

| Max. length of blank (m) | 9 |

| Max. punch hole (dia. × thi.) (mm) | Φ25.5 (round hole), 20 × 50 (oblong hole) |

| Punching force (kN) | 1000 |

| Shearing force (kN) | 1500 |

| Qty. of punch on each side | 4 + 2 + 2 |

| CNC axis | 3 |

| Feeding speed (m/min) | 45 |

| Punching speed (min⁻¹) | 40–50 times/min |

| Shearing mode | Single blade shearing |

| Item Name | Numerical Value |

|---|---|

| Angle steel size (mm) | L63 × 63 × 4—L140 × 140 × 10 |

| Channel steel size (mm) | 8#–18# |

| Band steel size (mm) | 70 × 5–180 × 10 |

| Max. length of blank (m) | 9 |

| Max. punch hole (dia. × thi.) (mm) | Φ25.5 (round hole), 20 × 50 (oblong hole) |

| Punching force (kN) | 1000 |

| Shearing force (kN) | 1500 |

| Qty. of punch on each side | 4 + 2 + 2 |

| CNC axis | 3 |

| Feeding speed (m/min) | 45 |

| Punching speed (min⁻¹) | 40–50 times/min |

| Shearing mode | Single blade shearing |

| Item | Value |

|---|---|

| Angle steel size (mm) | L140 × 140 × 10—L360 × 360 × 35 |

| Max. length (m) | 12 |

| Marking normal force (kN) | 1200 |

| Number character | 1 |

| Digit number of each group | 18 |

| Character size (mm) | 14 × 10 × 19 |

| The adjusting range of stadia (mm) | 40 – 340 |

| Drilling diameter (mm) | Φ17 – Φ40 |

| Max. speed of drilling spindle (r/min) | 6000 |

| The number of drilling spindle | Each side 3, a total of 6 |

| The hole of spindle | BT40 |

| The way of tool clamping | Pneumatic play knife / Broach rod |

| The number of CNC axis | 9 |

| The feeding speed of angle steel (m/min) | 40 |

| The way of cooling | High pressure spray cooling |

| Total power of machine | About 120 |

| Item | Specification |

|---|---|

| Band Steel size (mm) | 40 × 4—100 × 10 |

| Max. length of blank (m) | 9 |

| Max. punching (mm) | Round hole φ26, slot hole 21.5 × 40 |

| Punching force (kN) | 750 |

| Shearing force (kN) | 600 (can cut circle in band steel) |

| Qty. of punch surface | 1 |

| Qty. of punch (mm) | 3 |

| Qty. of punch on each side | Any |

| Marking normal force (kN) | 700 |

| Number character | 1 (12-character set) |

| The number of CNC axis | 2 |

| Speed of feeding car (m/min) | 90 |

| Punching frequency (min⁻¹) | 50–60 |

| Lubricating system | Equipped with automatic lubrication device |

| Item name | Specification |

|---|---|

| Dia. of Molding (mm) | φ150 — φ420 |

| Min. length of blank (mm) | 800 |

| Max. length of blank (mm) | 300 |

| Oil cylinder nominal force (kN) | 300 |

| No. of work table | 4 worktables (2 working simultaneously, other 2 assisting) |

| Item name | Numerical value | Notes |

|---|---|---|

| Punching force (kN) | 1000 / 1200 | |

| Marking force (kN) | 800 | |

| Thickness of plate (punching) (mm) | 5–25 | 20mm, Q345 |

| Max. size of workpiece (mm) | 1500 × 800 | 1500 × 1000, YBJ–100A |

| Max. dia. of punching hole (mm) | Φ25.5 | |

| Min. distance from hole to edge (mm) | 25 | Diameter ≤ 25.5mm |

| Punching speed (min⁻¹) | 40–50 | |

| Numbers of die | 3 | |

| Dimension of character (mm) | 14 × 10 × 19 | |

| Numbers of character | 10 | Adjustable as per user requirement |

| Process precision | Accordable with GB/T2694 |

| Item name | Numerical value | Notes |

|---|---|---|

| Punching force (kN) | 800 | |

| Marking force (kN) | 800 | |

| Thickness of plate (punching) (mm) | 5–20 | 16mm, Q345 |

| Max. size of workpiece (mm) | 800 × 500 | |

| Max. dia. of punching hole (mm) | Φ25.5 | |

| Min. distance from hole to edge (mm) | 25 | Diameter ≤ 25.5mm |

| Punching speed (min⁻¹) | 40–50 | |

| Numbers of die | 3 | |

| Dimension of character (mm) | 14 × 10 × 19 | |

| Numbers of character | 10 | Adjustable as per user requirement |

| Process precision | Accordable with GB/T2694 |

| Item name | Numerical value | Notes |

|---|---|---|

| Punching force (kN) | 1000 | |

| Marking force (kN) | 800 | |

| Thickness of plate (punching) (mm) | 5–25 | 20mm, Q345 |

| Max. size of workpiece (mm) | 1500 × 800 | |

| Max. dia. of punching hole (mm) | Φ25.5 | Diameter ≤ 25.5mm |

| Min. distance from hole to edge (mm) | 25 | |

| Numbers of die | 4 | |

| Dimension of character (mm) | 14 × 10 × 19 | |

| Numbers of character | 10 | Adjustable as per user requirement |

| Max. dia. of drilling hole (mm) | Φ50 | |

| Max. thickness of plate (drilling) (mm) | 40 | |

| Stroke of spindle (mm) | 180 | |

| Power of drilling spindle (kW) | 5.5 | |

| Process precision | Accordable with GB/T2694 |

| Item name | Numerical value | Notes |

|---|---|---|

| Punching force (kN) | 1200 | |

| Thickness of plate (punching) (mm) | 4–20 | 16mm, Q345 |

| Max. size of workpiece (mm) | 2000 × 1000 | |

| Max. dia. of punching hole (mm) | Φ28 / Φ80 / Φ100 | Accordable with thickness 4–20 / 4–10 / 4–5 |

| Min. distance from hole to edge (mm) | 25 | Diameter ≤ 25.5mm |

| Numbers of die | 6 | |

| Process precision | ±0.10 |

| Strength of tension (σb) | < 400 | 400–500 | > 500–600 |

|---|---|---|---|

| Steel plates | Q235 | Q345 | Stainless steel |

| Max. width of sloped edge (mm) | 20 | 16 | 12 |

| Max. thickness of plate (mm) | 45 | ||

| Scope of beveling angle (°) | 25–55 | ||

| Min. straight edge (mm) | 2 | ||

| Power of motor (KW) | 4 | ||

| Rotation speed of spindle (r/min) | 7.7 | ||

| Diameter of hob (mm) | 200 | ||

| Model | YGH–150 |

|---|---|

| Main cylinder pressure force (kN) | 1500 |

| Side cylinder pressure force (kN) | 500 |

| Steel pipe diameter (mm) | Φ300—1500 |

| Max. thickness of steel pipe (mm) | 25 |

| Max. length of steel pipe (mm) | 14000 |

| Model | GZH–1812 |

|---|---|

| Work table size (mm) | 15000 × 1000 |

| Length of steel pipe (m) | 6–12 |

| Flange diameter (mm) | Φ1800 |

| Steel pipe diameter (mm) | Φ1600 |

| Feeding speed (m/min) | 10 |

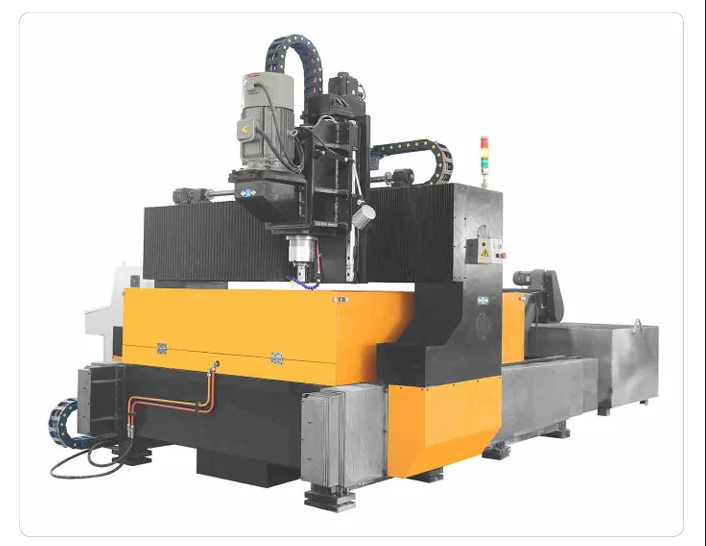

| Model | PMZ–16 | PMZ–2016 | ||

|---|---|---|---|---|

| Max. size of workpiece (L × W) (mm) | 1650 × 1000 | 2000 × 1600 | ||

| Max. thickness of workpiece (mm) | 80 | 100 | ||

| Max. drilling diameter (mm) | Φ50 | Φ50 | ||

| Principle axis | Quick change chuck | Morse taper hole #4, #3, #2 | ||

| Rotate speed (r/min) | 120–560 (Stepless speed regulation) | |||

| Feeding stroke (mm) | 180 | 180 | ||

| Motor power (kW) | 5.5 | 5.5 | ||

| Feeding mode | Hydraulic | Hydraulic | ||

| Hydraulic clamp | Clamping thickness (mm) | 15–80 | 35–100 | |

| Tongs number | 12 | 12 | ||

| Clamping force (kN) | 7.5 | 7.5 | ||

| Clamping switch | Footswitch | Footswitch | ||

| Motor power | Servo motor (kW) | 1.0 / 1.0 | 1.5 / 1.5 | |

| Hydraulic motor (kW) | 2.2 | 2.2 | ||

| Cooling motor (kW) | 0.25 | 0.25 | ||

| Model | PMZ–2016H | |

|---|---|---|

| Max. Size of Workpiece | L × W (mm) | 2000 × 1600 |

| Max. thickness of workpiece (mm) | 100 | |

| Principle axis | Number of spindle | 1 |

| Morse taper | BT50 | |

| Max. drilling diameter (mm) | Φ50 | |

| Rotate speed (r/min) | 0–2000 | |

| Motor power (kW) | 15 | |

| CNC axis | Number of CNC axis | 3 |

| Servo motor power (kW) | 1.5 / 2.0 / 2.0 | |

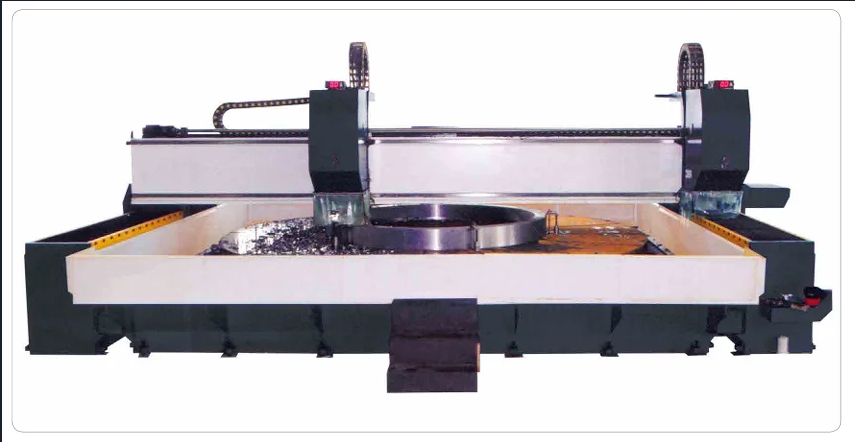

| Category | Specification | Model | ||

|---|---|---|---|---|

| GZD2500/2 | GZD4000/2 | GZD5000/2 | ||

| Workpiece | Max drilling distance (L × W) (mm) | 2500 × 2500 | 4000 × 4000 | 5000 × 5000 |

| Max Process Thickness (mm) | 250 | |||

| Work Table | T–slot form | The vertical and horizontal form | ||

| Spindle drilling head | Number | 2 | ||

| Taper hole of spindle | BT50 | |||

| Max Dia. of drilling (mm) | Φ50 | |||

| Tapping | M8–M20 | |||

| Spindle rotation speed (r/min) | 0–4000 | |||

| Spindle motor power (kW) | 22 (optional) | |||

| Longitudinal Movement of Gantry (X axis) | Max. stroke (mm) | 2500 | 4000 | 5000 |

| Moving speed of X axis (m/min) | 0–8 | |||

| Servo motor power (kW) | 3 × 2 | |||

| Transverse Movement of Drilling Head (Y axis) | Max. stroke (mm) | 2500 | 4000 | 5000 |

| Moving speed of Y axis (m/min) | 0–8 | |||

| Servo motor power (kW) | 3 × 2 | |||

| Feeding of Vertical ram (Z axis) | Max. stroke (mm) | 500 | ||

| Moving speed of Z axis (m/min) | 0–8 | |||

| Servo motor power (kW) | 3 × 2 | |||

| Positioning precision | X, Y axis (mm) | ≤ ±0.1 (Over all length) | ||

| Swarf cleaner | Type | Plate chain type | ||

| Quantity | 1 | 2 | 2 | |

| Swarf cleaning speed | 1.5 | |||

| Motor power (kW) | 0.75 | 2 × 0.75 | ||

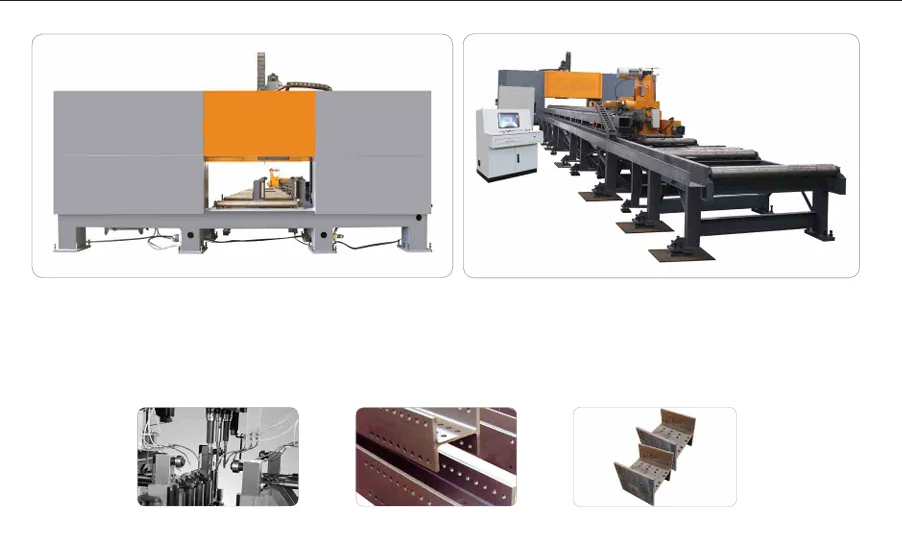

| Specification | Model | ||||

|---|---|---|---|---|---|

| SWZ400H | SWZ500H | SWZ700H | SWZ1000H | SWZ1250H | |

| Minimum size (mm) | 100 × 75 | 100 × 75 | 150 × 75 | 150 × 75 | 150 × 75 |

| Maximum size (mm) | 400 × 300 | 500 × 500 | 700 × 500 | 1000 × 500 | 1250 × 600 |

| Thickness (mm) | ≤ 30 | ≤ 30 | ≤ 40 | ≤ 50 | ≤ 55 |

| Processing length (m) | 1–12 | 1–15 | |||

| Number of spindles | 3 / 9 | ||||

| Spindle rotation speed (r/min) | 120–560 (optional 30–6000) | ||||

| Axial feed speed (mm/min) | 20–200 | ||||

| Spindle feed stroke (mm) | 180 | ||||

| Maximum borehole diameter (mm) | Φ40 | ||||

| Feeding trolley travel (m) | 13 | 17 | |||

| Length of cutting track (m) | 8 | 10 | |||

| Specification | Model | |

|---|---|---|

| BM38/6 | BM38/12 | |

| Flange width (mm) | 20–1000 | |

| Web height (mm) | 100–600 | |

| Flange thickness (mm) | 6–38 | |

| End-incline (mm) | ≤ 300 | |

| Length (mm) | ≥ 400 | |

| Quantity | 2 | 4 |

| Rotation speed of spindles (r/min) | 250 | |

| Motor power of spindles (kW) | 2 × 7.5 | 4 × 7.5 |

| Up/down speed (mm/min) | 125–500 | |

| Motor power for up/down (kW) | 2 × 1.5 | 4 × 1.5 |

| Longitudinal slipway stroke (mm) | 300 | |

| Transverse slipway stroke (mm) | 850 | |

| Slipway speed (mm/min) | 400–1600 | |

| Motor power for slipway (kW) | 2 × 0.25 | 4 × 0.25 |

| Clamping speed (mm/min) | 450 | |

| Clamping motor power (kW) | 2 × 0.37 | 4 × 0.37 |

| Boost ratio | 11.1 | |

| Clamp force (kN) | 3.5–8 | |

| Adjustment (mm) | 0–40 | |

| Motor power (kW) | 2 × 0.04 | 4 × 0.04 |

| Model | BS1250 | BS1000 | BS1000A | BS750 | BS500 |

|---|---|---|---|---|---|

| Sawing capability (round steel) | Φ660 | Φ660 | Φ660 | Φ550 | Φ320 |

| Sawing capability (square steel) | 630 × 630 | 550 × 550 | 550 × 550 | 480 × 480 | 300 × 300 |

| Sawing capability (H-beam) | 1250 × 600 | 1000 × 500 | 1000 × 500 | 750 × 450 | 500 × 300 |

| Saw blade size (mm) | T:1.6, W:54, L:8300 | T:1.6, W:54, L:7600 | T:1.6, W:54, L:7600 | T:1.3, W:41, L:6850 | T:1.3, W:41, L:5790 |

| Saw blade line speed (m/min) | 20–80 | ||||

| Table height (mm) | 800 | ||||

| Feeding speed | Stepless feeding | Program controlled | Stepless feeding | ||

| Rotation angle | 0° – 45° | 0° | |||

| Project Name | Numerical Value | ||

|---|---|---|---|

| 800 | 1000 | 1200 | |

| Punching force (KN) | 800 | 1000 | 1200 |

| Workpiece thickness (mm) | 12 | ||

| Workpiece size (mm) | 2000 × 800 | 2500 × 800 | 4000 × 800 |

| Number of clamps (pcs) | 2 | 3 | |

| Number of molds (pcs) | 9 (customizable) | ||

| Punching diameter (mm) | Φ50 (customizable) | ||

| Relocation function | Available | ||

| Way to control | Numerical control system | ||

| Total machine power (kW) | ≈ 25 | ||

| (Length × width × height) (m) | ≈ 4.5 × 5 × 2.5 | ≈ 5.5 × 5 × 2.5 | ≈ 8.5 × 5 × 2.5 |

| Machine weight (T) | ≈ 12 | ≈ 13 | ≈ 18 |

PROMECHSOLUTION is a leading provider of industrial automation and machinery services, offering a diverse range of products and services that combine human intelligence with cutting-edge AI technology.